Specifications :

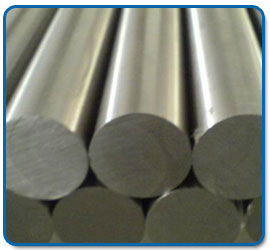

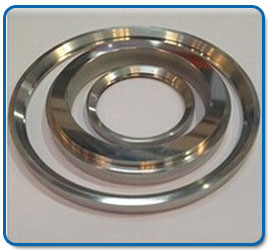

Range : ½”NB to 48″NB in

Dimensions : ANSI/ASME B16.11 & BS3799, etc.

Standards : ASTM B366, ASTM A403

Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type : Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Form : Tee, Union, Full Coupling, Half Coupling,Elbow 45 Deg & 90 Deg, Swage Nipple, Cross, Cap, Plug Bush.

Grades : UNS No. S31254

Grades : 202, 303, 304, 304L, 310, 316, 316L, 32, 410, 420, 416, 430, 431, 430F & others

Thread Type : ANSI B1.1 Class 2A Fit

Diameter (Size) : M8 to M40 (5/16 ” to 1--1/2 ”)

With a high resistance to corrosion, 17-4 PH Stainless Steel is one of the many stainless steel options Altemp Alloys offers. 17-4 PH is an economical alternative to other stainless and strong carbon steels

Specifications: